Electrical Inspection: Panels and Wiring

Now that we’ve taken a look at all the small things, let’s turn our attention to the main panel. As mentioned earlier, electrical systems, like a car or any other system that functions as many parts in simulations operation, need maintenance. The general rule is an update every 10 years, and replacement every 30 years. So for many of us, that can put us overdue on both.

Now let’s take a look at something very simple. The name brand. This isn’t to bash or certain brands or promote others. Its simply to rule out the possibility that you don’t have a one of a few known brands known as fire hazards. Federal Pacific, and Zinsco.

If your panel has one of these names or looks similar, you might want to go ahead and put this on your list to be addressed. These two panels were installed in the early to mid-70s, and they were mass produced. So don’t feel too singled out if you are one of the unlucky contestants on our game of fire hazard bingo. In our area especially, spec home builders installed these by the thousands so we are still in the process of zoning them out.

Panel Location

Now let’s talk about the location. Most homes have the panel located in either the basement or the garage. There are always certain homes we have seen where that was not the case, and some are quite surprising. Weve seen them in the attic, inside a kitchen cabinet, above a toilet, in the middle of a stairwell and all kinds of interesting places. Let’s just start off with the places there are not allowed.

Clothes closets (or near easily combustible material)

Countertops (kitchens are fine, just not on the countertop)

Bathrooms

Over steps (unless its on a large landing)

If your panel happens to fall in one of these locations, get that pen out and add this one to your list. We have seen this one be a major hang up when trying to close on a house. But keep in mind every situation is different, and you never know until you know.

Panel clearance

Part of the reason these locations are not ideal, thus illegal for panels, is mostly related to clearance issues. The main idea is safety. We need to be sure first off that someone can get to the panel for basic maintenance. So if you hare having to move shelves or stacks of boxes just to get to your panel, lets address that first. The hard and fast rules code states on panel clearance is this.

36 inches directly in front of the panel, and the width of the panel from the floor to the ceiling.

This area must be free from obstruction including debris. So the best way I have heard it described is this. Imagine a refrigerator pushed up against your electrical panel. There can be nothing in the way inside that zone. There is also the matter of what may be in the same wall or surrounding wall space. Let’s just simplify it to this. If there is a water, drain or gas line above or below the panel in the same wall space, write this down as a potential issue to fix. Again many jurisdictions are different when it comes to this but its better to be prepared with proper expectations that be caught off guard.

Wiring

Take a long look around your panel. Odds are its in an unfinished space, and you can easily see the wiring as it comes out to feed the home. There is really only a few kinds of wiring we need to be very aware of, as they will most likely open that dreaded can of worms.

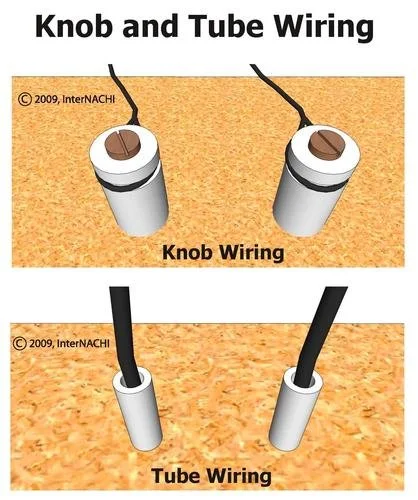

“Knob and Tube” was the first wiring mass produced to be installed in homes. (1880 – 1940s) It was a great product for its time and accomplished the job it was expected to do.

Obviously as time went on and technology changed, the demand for the standard homes electrical systems dramatically increased. Not only that but we realized the need for grounding throughout the home, as well as the importance of dedicated neutrals. Due to the sheer age of the product, the insulation is typically in rapid decay, and it’s actually illegal to insulate any area where it is installed. If your home has knob and tube, rest assured there are many different ways to approach it and many solutions. But you are most likely on your way to seeking one of them.

The next wiring in question would be one called “rag cloth.”

This is the wiring that replaced knob and tube in the electrical industry. (1940 – 1950s) This was a superior product but unfortunately most of it was made and installed before the electrical field figured out proper grounding and neutral properties. So even though its insulation and overall makeup is superior, once again you are left without proper grounding. There are some models that were made at the end of its useful life that include a ground, but unfortunately due to the limited understanding of an industry still figuring things out, it is undersized. If rag cloth wiring is the type of wire in your home, lets write it down. There are several videos on our website and YouTube page that break down detail the dangers and solutions to all kinds of residential wiring.

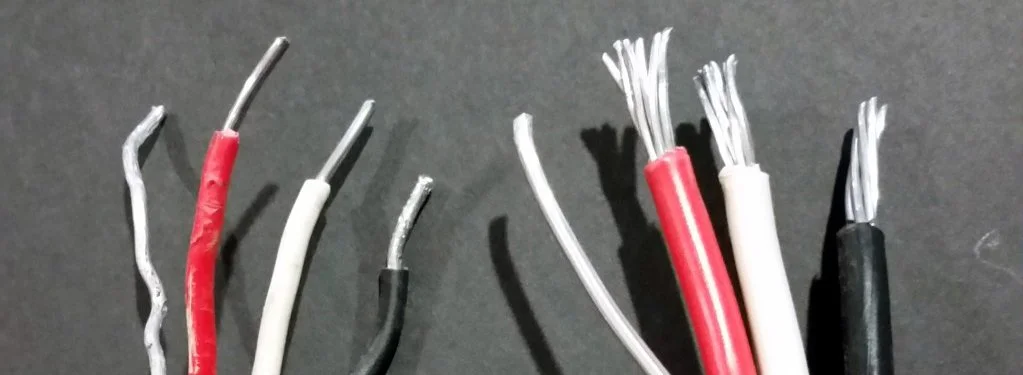

The final wiring to round out our list of potential hazards is Aluminum.

Due to the sudden escalating price of copper, aluminum wiring was sometimes substituted for branch circuits. (1960 – 1970s) Over time, the industry found out the shortcomings of aluminum as certain qualities of the metal did not stand up to demands. Faulty connections became too frequent and the installation became illegal due to the fire hazards. As costs are still a factor in electrical installations, we still use Aluminum today but only for service feeders. So if you see the silver metal feeding your meter or from your meter to your panel, you are most likely out of the woods. But if you see aluminum branch circuits feeding out to the main house for lighting and receptacle power, grab your list and add this one to it.